SCRUBBER (GAS WASHING SYSTEM)

Ambient air creates a complex volume of particles and gases. It can be found in unwanted particles and gases in this volume. Scrubber systems are used to eliminate these unwanted particles and gases in the environment.

We can explain the system in the industry as follows;

Systems that perform the process of washing the ambient air with liquids in order to remove or neutralize the unwanted particles and particles in its content are called scrubbers.

So why are there unwanted particles and gases in the ambient air;

Particulate particles are solid or liquid substances, but they can remain suspended in the air environment due to their very fine grain size. They may be too small to be seen or seen with the naked eye. It consists of particles such as dust or moisture of any substance, ash, soil, bacteria, pollen, soot that can pollute the air and have negative effects on living things. Likewise, it has negative effects on gases that pollute the air such as particulate parts. Many gases such as carbon monoxide (CO), sulfur dioxide (SO2), nitrogen oxides (NOx) also cause toxic effects on living things and humans.

It causes air-polluting particles and gases to develop respiratory infections, allergic and toxic effects on living things and humans. In addition, many of them are carcinogenic. It creates bad odors in the air and shows the effects of reducing the quality of life. Due to these negative effects, they are not required to be in the ambient air.

These hazardous particles and gases, especially in industry and other areas, should not be allowed to be released directly to the atmosphere, and air pollutants should be prevented by using filter systems.

We can basically divide filter systems into dry filter systems and wet filter systems. Systems that are more advantageous and efficient may be preferred. Scrubber systems are generally considered as wet filter systems.

How do scrubber systems work?

The system first collects the ambient air with the help of fans and sends it into the scrubber tower. The air coming into the scrubber tower is washed with a washing chemical liquid. During this washing, the washing chemical liquid absorbs or neutralizes the unwanted particles and gases. Cleaned air is released into the atmosphere through the chimney of the scrubber tower.

In order for scrubber systems to work efficiently, the air collected from the environment should be brought together with the washing chemical liquid at the maximum level. Perforated plates or parts called raschig rings that enlarge the contact area inside the tower are used to increase the contact area of the air-washing chemical liquid. The larger the contact area, the more efficient the washing process will be.

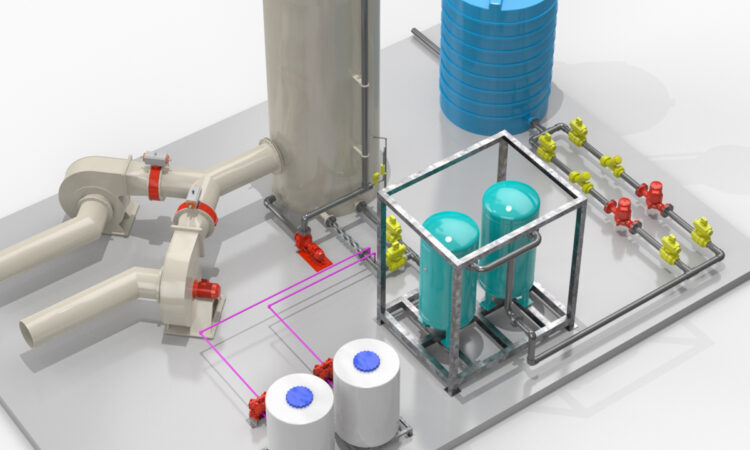

What types of equipment and instruments do scrubber systems include?

The system has a active structure in itself. There are both gas flows and liquid flows in the system. It contains gas and flow control processes. These processes are controlled by automation units designed fully automatically. It is supported by SCADA software that can instantly collect information from the system in order to monitor the operation of the system.

The system includes pumps, fans, plumbing lines, fittings materials, gas detection sensors, flow control systems, plc and scada systems, ventilation lines, chimney systems, liquid storage tanks, liquid and powder preparation units, liquid and powder dosing units.

What are the application areas of the scrubber system?

- Odor control systems

- Wastewater treatments and pumping stations

- Drying and incineration plants

- Industrial plants (chemical, pharmaceutical, paint and food industry)

- exhaust gas purification

- Composting facilities

What are the types of scrubber system?

- Chemical scrubber systems (SOx, NOx)

- Biological scrubber systems (odor treatment)

- Venturi scrubber systems (particles, ash, soot)

- Mercury scrubber systems (heavy metal)

Which washing liquids are used in the scrubber system?

- Sodium hydroxide (caustic) (NaOH)

- hydrochloric acid (HCl)

- hypochlorite (ClO)

- other wasing liquids

What kind of materials are scrubber systems made of?

Basically, they can be produced from any material that is physically in the form of sheets and can be assembled. However, choosing materials that are resistant to liquids and chemical properties, resistant to corrosive liquids, and resistant to separating acidic and basic liquids will help the system to be used for many years. For this reason, stainless steel types (chrome-nickel alloy ones) and plastic sheet types can be selected. Some types of materials that are economical and easily available in the market can be listed as follows.

- Steel materials (AISI 304, AISI 316, DUPLEX materials)

- Plastic materials (polypropylene, polyethylene materials)

- Composite materials (glass reinforced polyester materials)

How should scrubber selection be made?

- Selection of ventilation system;

For selection, first of all, a ventilation system should be created according to the volume of the environment where the dirty air will be collected. The flow rate of the pollutants in the environment should not be more than the capacity of the ventilation system that collects dirty air from the environment. The ventilation system must be designed more than the flow rate of the pollutants. Otherwise, the ventilation is not deemed to be made properly and cannot function.

- Selection of the scrubber tower;

In order for the contaminants collected from the environment to be completely neutralized with the scrubber liquid in the scrubber tower, the volume of the tower and the total surface area of the washing place should be adjusted according to the flow rate of the pollutant. Pollutants with high flow cannot meet well with the washing liquid in towers that do not have sufficient volume, they cannot be neutralized in the desired amount.

Manhole entrances should be available where necessary to be used for maintenance and repair interventions to the tower. These manholes should be accessible safely and easily.

The exit chimney of the tower should not be under the buildings in the environment. It should be at least two or three meters higher than the nearby buildings. In addition, there should be jetkep at the end of the chimney that protects against wind and precipitation.

- Selection of washer fluid type and preparation system;

The right washer fluid must be selected according to the type of contaminants. Acidic-basic values should be taken into consideration to ensure neutralization. Sufficient amount of washer should be used according to the pollutant flow rate. Yıkayıcı sıvı sürekli yenilenmeli ve konsantrasyonu stabil tutulmalıdır.

With the circulation of the washing liquid, the total amount used should be reduced, ie the cost of the washing liquid amount should be reduced. However, it may be necessary to keep the circulation flow rate high in order to increase the penetration with the pollutant. Therefore, dosage units that prepare quality solutions should be used. Systems that can instantly adjust the quality of the washer should be preferred.

- Selection of the material quality of the materials to be used in the system;

Before the system is installed, many factors such as the type of all chemical substances included in the system, their PH values, corrosion effect, ambient temperature, the altitude of the installation site, ambient humidity should be considered.

All these factors should be calculated and the material quality should be chosen accordingly. It should not react with chemical substances, should not react, should be resistant to acidic and basic values, should be resistant to rust, should be resistant to heat if high temperature will occur or if a hot washer is to be used, if the altitude of the installation place is high, insulation should be made to prevent freezing of plumbing and liquids in winter environment or heaters. It should be used, devices with sufficient protection resistant to humid environments should be selected.

- Selection of electrical devices and instruments;

The electrical efficiency of the pump and fan motors to be used for the system is important in reducing energy consumption. In addition, the insulation class is also important in terms of climate and environmental conditions. An insulation class that will withstand moisture and water should be selected, and ATEX values should be considered for equipment to be used in flammable and explosive atmospheres.

The plc system, scada software, gas detection sensors, instant tracking sensors, electrical instruments and parts, solenoids, cable and cable organizer parts to be used in the system should be carefully examined and selected. The system can work best with synchronized operation of all these materials.

What are the advantages of the scrubber system?

- Investment costs are low.

- It can work for many years at maximum efficiency.

- When the system is installed correctly and fully equipped, the need for personnel is very low.

- They are capable of meeting very high pollutant flow rates.

- Maintenance and repair costs are low as easily available materials and parts are used in the market.

- The training time required to operate the system is short.

- Since it is manufactured modularly, it is easy to transport and installation takes a short time.

- Since it can be coupled gradually, there is no need to re-invest in capacity increase.

- When the system is examined in terms of the work it performs, the installation area is less required.